Reciprocating rod lifting has always been the main artificial lifting method for onshore oil wells. The continuous up and down movement of the sucker rod will cause excessive friction between the sucker rod and the tubing, which may cause the sucker rod and tubing to be premature due to excessive wear. Invalidate. If it is not checked, expensive repairs are usually required.

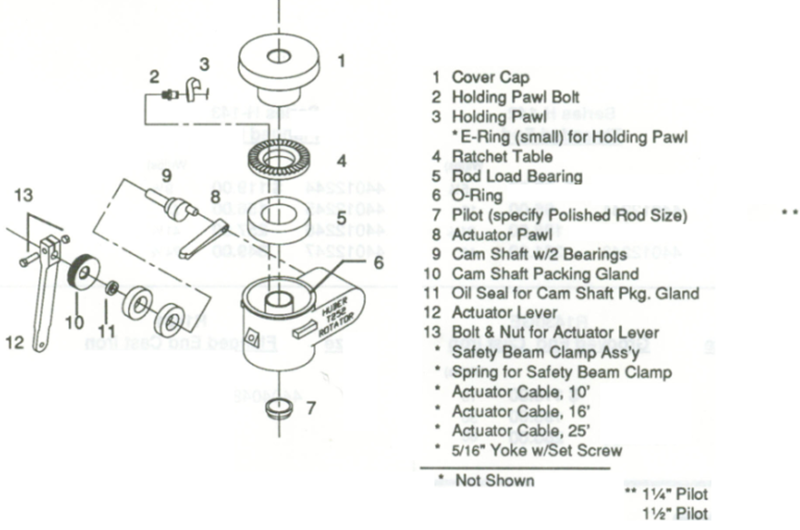

In order to prolong the service life of sucker rods, the traditional sucker rod rotator that has been used since the 1950s is a ratchet mechanism that gradually rotates the rod with each stroke. Rotation distributes the wear evenly on the circumference of the rod and coupling instead of isolating the wear to one side. The rod rotator is a mechanical device installed on the polishing rod between the bracket and the polishing rod clamp. Each stroke causes the rod to rotate gradually. The rotating mechanism with the actuator lever arm is connected to the walking beam by a metal wire. When the surface unit moves up and down, it pulls and releases this metal string to move the actuator lever arm up and down. The rotating mechanism is activated, which will slowly rotate the polished rod and the pole below.

The rotation of the rod string will disperse the friction and wear caused by the interference between the rod and the pipe. This will make the rod wear more evenly distributed around the rod, instead of confining this wear to only one point, and will help maximize the life of the rod.

In addition, the rod rotation used in conjunction with the rod guide is the most effective way to remove paraffin between the rod and the pipe.

Guqin instrument for sale

Guqin instrument for sale